In the symphony of a motorcycle's engine, the exhaust note often takes center stage. But the deep rumble of a cruiser or the sharp scream of a sportbike is merely the final outcome of a complex process that begins at a critical, yet often overlooked, component: the motorcycle exhaust manifold. Commonly referred to by riders as the "exhaust header" or simply "headers," this is not just a pipe to direct fumes away. It is a meticulously engineered component that plays a pivotal role in performance, efficiency, and the very character of the machine.

This article delves into the world of the motorcycle exhaust manifold, exploring its function, the science behind its design, the different materials used, and the impact of aftermarket upgrades.

What is a Motorcycle Exhaust Manifold?

The motorcycle exhaust manifold is the assembly of pipes that bolts directly to the engine's cylinder head(s), collecting hot, high-pressure exhaust gases as they exit the combustion chamber and funneling them into the rest of the exhaust system. On a multi-cylinder engine, its primary task is to merge the flow from individual cylinders into a single collector pipe before the gases travel through the muffler and out into the atmosphere.

While it may look like a simple set of bent tubes, its design is governed by complex principles of fluid dynamics and wave theory. Its shape, length, and diameter are all critical variables that engineers manipulate to extract maximum performance from the engine.

The Critical Functions: More Than Just Venting

The manifold's role extends far beyond being a passive conduit for exhaust. Its core functions are:

1.Gas Evacuation: Its most basic job is to safely and efficiently remove spent exhaust gases from the combustion chamber. A poor design can lead to "backpressure," where gases cannot escape quickly enough, choking the engine.

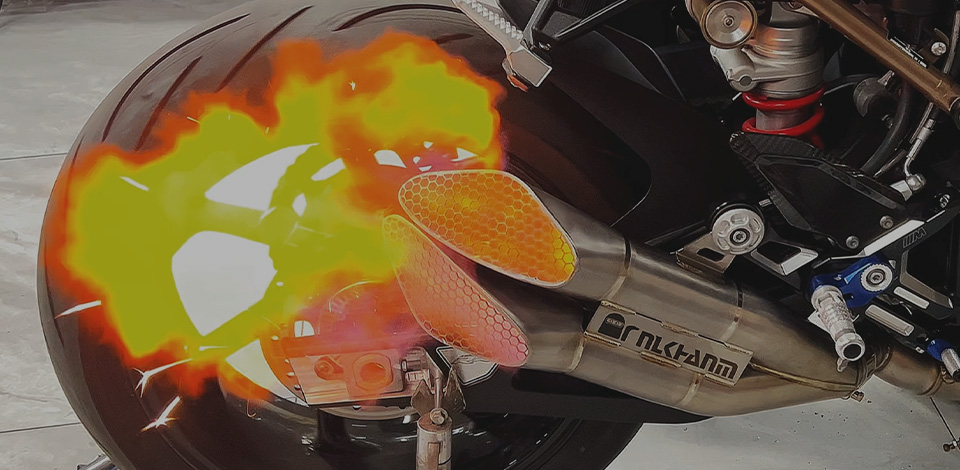

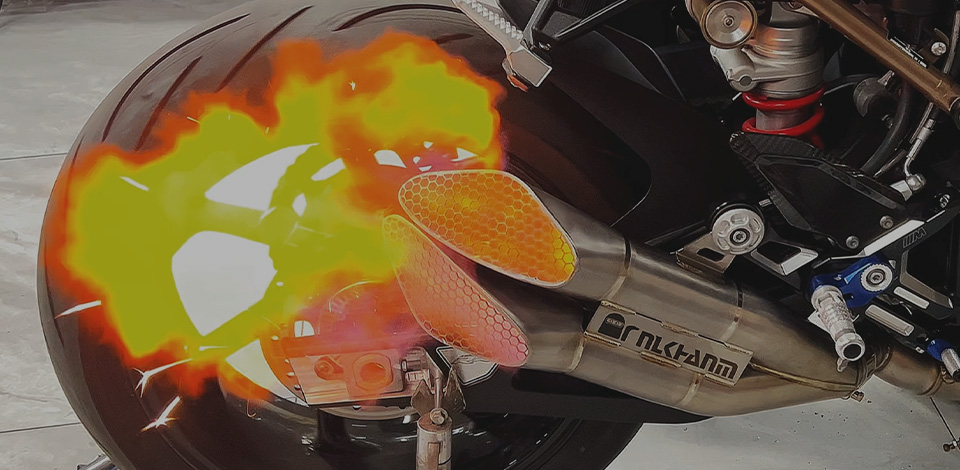

2.Scavenging and the Pulse Effect: This is where the real magic of a well-designed motorcycle exhaust manifold happens. As a high-pressure pulse of exhaust gas exits a cylinder and travels down the header pipe, it creates a low-pressure wave behind it. This negative pressure pulse can help "suck" or scavenge the remaining exhaust gases out of the cylinder and, remarkably, even help draw in the fresh air-fuel mixture for the next combustion cycle. On multi-cylinder engines, the header pipes are often tuned so that the exhaust pulse from one cylinder aids in scavenging the next, creating a harmonious and efficient extraction process.

3.Performance Tuning: The dimensions of the manifold are a key factor in an engine's power band.

★Header Diameter: A larger diameter pipe allows for higher flow, which is beneficial for high-RPM, high-horsepower engines. A smaller diameter maintains exhaust gas velocity at lower RPMs, which improves low-end and mid-range torque.

★Header Length: The length of the pipe between the cylinder head and the collector is crucial for tuning the scavenging effect. Longer headers generally enhance low-end torque, while shorter headers shift the power band higher up the RPM range. This is why cruisers, which prioritize low-end grunt, often have long, sweeping headers, while top-fuel drag bikes have incredibly short, stubby ones.

4.Structural Integrity: The manifold must withstand extreme and constant thermal cycling—heating to near-glowing temperatures and cooling back to ambient, repeatedly. It also needs to handle the engine's vibrations without cracking at the flanges or welds.

Materials: From Cast Iron to Aerospace Alloys

The choice of material for a motorcycle exhaust manifold significantly impacts its performance, durability, and cost.

★Mild Steel: The most common material for stock and many aftermarket systems. It's cost-effective and durable but is prone to rust and corrosion from the inside out due to moisture in the exhaust gases. It's often coated with a high-temperature paint or chrome for protection.

★Stainless Steel: A massive upgrade over mild steel. Stainless steel exhaust headers are highly resistant to corrosion and can withstand very high temperatures. They are stronger, thinner-walled (which can save weight), and maintain a handsome, polished appearance for years. Grades like 304 and 409 are industry standards for performance exhausts.

★Titanium: The ultimate choice for high-performance and racing applications. Titanium exhaust manifolds are incredibly strong and about 40% lighter than stainless steel. They have excellent heat resistance, but their cost is prohibitively high for most casual riders. The iconic blue and purple heat discoloration of a titanium header is a recognized badge of performance.

★Inconel: This nickel-chromium superalloy is found on the most extreme machines, like MotoGP bikes and top-tier race replicas. Inconel can withstand temperatures that would melt other metals, is exceptionally strong, and is highly fatigue-resistant. Its cost is astronomical, reserved for the pinnacle of motorcycle engineering.

Stock vs. Aftermarket Headers: The Performance Debate

Many riders consider upgrading their stock motorcycle exhaust manifold as a key first step in performance modification. The reasons are compelling:

★Increased Power and Torque: Aftermarket headers are often designed with performance as the primary goal. They feature optimized diameters, smoother bends, and better merging collectors to improve exhaust flow and scavenging, resulting in measurable gains in horsepower and torque across the RPM range.

★Weight Reduction: Replacing a heavy, bulky stock manifold (sometimes a cast iron unit) with a sleek set of thin-walled stainless steel or titanium headers can shave several pounds off the motorcycle, improving handling and acceleration.

★Aesthetic Appeal: The look of a gleaming, aftermarket header is a major draw. It transforms the appearance of the motorcycle's engine bay, offering a more aggressive and purposeful look.

However, it's crucial to understand that simply bolting on a new manifold is rarely a plug-and-play solution for maximum power. The engine is an integrated system. A freer-flowing exhaust often requires an accompanying upgrade to the air intake and a fuel management controller or an ECU remap to adjust the air-fuel ratio. Without this, the engine may run too lean (too much air, not enough fuel), which can cause overheating and potential engine damage.

The Collector: Where the Tubes Meet

The design of the collector—the section where the individual header pipes merge—is as important as the headers themselves. A well-designed collector manages the merging exhaust pulses to enhance scavenging and minimize turbulence. "4-into-1" systems are popular on sportbikes for top-end power, while "4-into-2" or "2-into-1" systems are common on cruisers and nakeds, often offering a broader power band.

Maintenance and Common Issues

The motorcycle exhaust manifold operates in a hostile environment and is subject to several common problems:

★Exhaust Leaks: Often caused by a failed gasket between the manifold and the cylinder head, or by warped flanges. A tell-tale "tick-tick-tick" sound on startup or acceleration is a classic symptom.

★Rust and Corrosion: The enemy of mild steel systems. Internal condensation, especially from short trips where the system never fully heats up, accelerates this process.

★Cracking: Constant heating/cooling cycles and engine vibration can lead to fatigue cracks, typically at the welds or sharp bends.

★Discoloration: Blue and gold tints on stainless steel headers are normal and a sign of heat cycling. However, a single header pipe turning a different color than the others can indicate a fueling issue on that specific cylinder.

Conclusion

The motorcycle exhaust manifold is a masterpiece of functional engineering, transforming raw, chaotic exhaust pulses into a tuned force that enhances performance. It is the gateway between the controlled explosion within the engine and the world outside. Understanding its purpose, materials, and tuning principles allows a rider to appreciate not just the sound their bike makes, but the intricate dance of physics that makes it possible. Whether you're a casual rider or a performance enthusiast, the humble header pipe deserves its share of respect as a key component in defining your motorcycle's soul and capability.

motorcycle exhaust manifold

exhaust installation

exhaust pipe motorcycle

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

Slovenčina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Māori

नेपाली

Oʻzbekcha

Беларуская мова

ʻŌlelo Hawaiʻi

íslenska

Kinyarwanda